- GST No. 24AAQCA6724L1ZA

- Send SMS

- Send Email

19.50 Lac / Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Aaspa |

| Driven Type | Electric |

| Color | Grey |

| Click to view more | |

Product Details

Condition

New

Power

9-12kw

Automation Grade

Semi Automatic, Manual, Fully Automatic, Automatic

Certification

ISO 9001:2008

Voltage

440V

Type

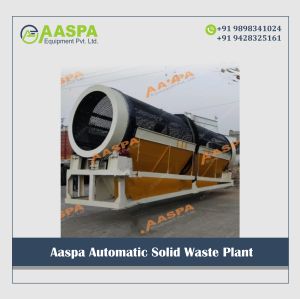

Solid Waste Compost Plant

Weight

4000-5000kg

Warranty

5yrs

Country of Origin

India

Usage/Application

Industrial

Treatment Capacity

100 TPD

Power Source

Electronic

Space Requirement

MS 2500

Product Code

AASPA 2356

Payment Terms

L/C, D/A, D/P, T/T, Other

Packaging Details

AASPA

Advantages and Features

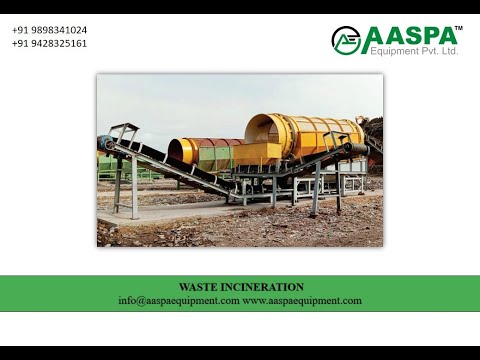

- Designed to fit your operation- Trommel screen can be customized to meet different capacity and working site

- Free from pollution- Fully enclosed structure,no dust pollution,improve working conditions for operators as well

- Variable application range-Compost,chemical,coal,plastic,recycling,metallurgy,mineral-selecting etc.

- Superior design-Simple structure,easy maintenance,steady operation,low energy consumption

- Less blockage-Automatic cleaning brush on the top of trommel screen to avoid the blockage

- Screen long life span-Screen is made of 16Mn with strong strength, good abrasion resistance and high screening efficiency.

- Today's MSW management systems are highly integrated and include various options in materials collection, materials recovery, composting, combustion and landfilling. A Materials Recovery Facility (MRF) is where recyclable materials that are collected from households are sorted into different types (e.g. plastics, cardboard, paper, metal) using a mixture of manual and automated methods. When the materials have been sorted they are sent to reprocessors and manufacturers where they are used to create new products. The main function of the MRF is to maximize the quantity of recyclables processed, while producing materials that will generate the highest possible revenues in the market. The mechanical sorting mechanisms and processes include: conveyors, tromell screens, sorting stations, ballastic screens, ferrous and non ferrous separators, optical sorters, bag breaker, and balers. Processing at the facility begins mechanically, becomes manually and then goes back to a mechanical process for final quality control. The result is unparalleled diversion and consistently cleaner product.

- MRF include

- Conveyor System Ferrous Metal Separation Screening Air/Density Classcation Non Ferrous Metal Separation Manual Sorting /Separation of Various inputs Size Reduction Baler and compactor.

- For the size reduction of :

- • Medical waste • Municipal Solid Waste • E-waste • Pharmaceuticals • Plastic • Aluminium Cans and Bins Biomass • Agricultural Waste • Card Board • Containers • Electrical wires • FRP • Hazardous waste • Hotel/Kitchen waste • Industrial waste • Jute • Laminates • Oil Filters • Tyres • Pet Bottle • Packaging Waste • Rubber • Textile • Vinyl • Automobile waste • Any other type of waste

Looking for "Municipal Solid Waste Composting Plant" ?

Piece